Explore our PowerUP Articles

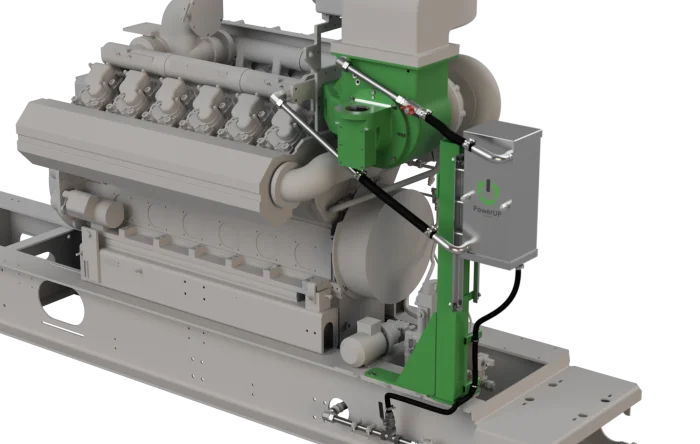

Welcome to the PowerUP Blog! Here’s where you’ll find the latest on innovations e.g. for gas engine updates, condition based overhaul, new gas engine spare parts or container solutions, and insights into the energy sector. From deep dives into biogas and natural gas to information and updates on Jenbacher® and MWM® engines, here you can power up your knowledge. Whether you’re in the industry or just energy-curious, join us as we explore the future of power together.

Featured articles

Biogas transforms organic waste into renewable energy — but the source of that waste matters. From manure and food scraps to industrial byproducts, feedstock quality impacts efficiency, methane yield, and system performance. Explore the 5 best biogas sources and how PowerUP helps optimize energy output from any feedstock.

Biogas is already in use across farms, municipalities, and industries, but does it have a future? This article explores the challenges, opportunities, and innovations shaping the long-term role of biogas in energy systems.

Biomass is organic material used to produce renewable energy. This article explains what biomass is, where it comes from, how it’s used, and what role it plays in today’s energy systems.

Anaerobic digestion is a natural process that converts organic biomass into renewable energy and nutrient-rich fertilizer. This article explains how it works, what it produces, and why it’s becoming a valuable part of the energy transition.

Subscribe to the PowerUP Innovation-Letter

Get the the latest innovations and upgrades regarding gas engines delivered to your inbox each month.

All Articles

From natural gas to innovative renewable options like biogas and hydrogen, discover the flexibility that makes Jenbacher® engines leaders in sustainable power generation. Let’s dive into it!

This blog post explores the company’s evolution from its modest origins to its status as a global player in providing efficient, sustainable power solutions.

Learn about the distinctive attributes, operational efficiency, and sustainability of each series, from the versatile Type 2 and Type 3 to the powerful Type 9. This guide shows how Jenbacher® engines drive innovation in the power generation sector, setting new standards for performance and environment.

From detailed breakdowns of each engine series to their innovative applications across various industries, this guide provides a comprehensive overview of Jenbacher® engines’ efficiency, versatility, and commitment to sustainability.

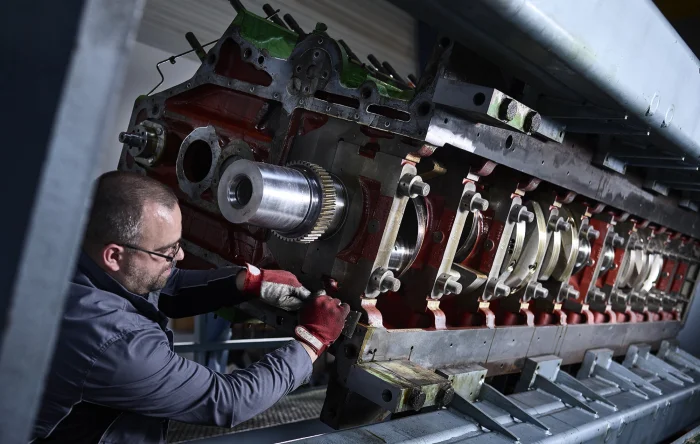

Dive into the world of Jenbacher® engine rebuilds and see how these gas engines get a second life. Learn about the steps involved in restoring an engine to peak performance, from disassembly and inspection to reassembly and testing.

Jenbacher® engines are renowned for their efficiency in converting fuel into energy. They operate on the principle of internal combustion, where a mixture of air and fuel is ignited to produce power.

Learn how these advanced engines transform fuel into power while maintaining high efficiency and low emissions.

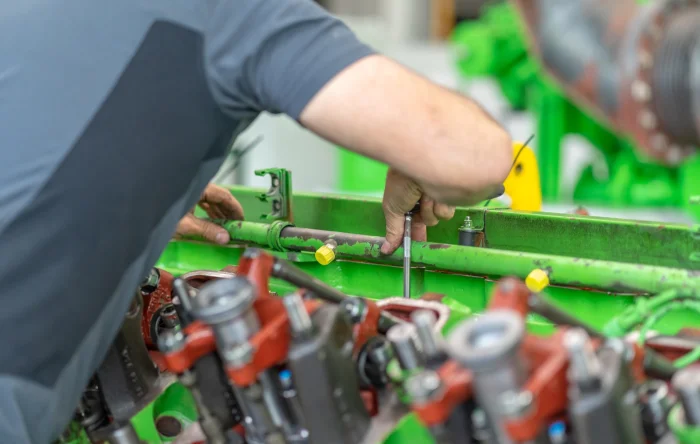

When gas engines underperform or age, choosing between remanufacturing, rebuilding, or overhauling is crucial. This article explains the differences and highlights how PowerUP’s condition-based overhauls offer targeted, cost-effective solutions to restore engine performance and extend service life.

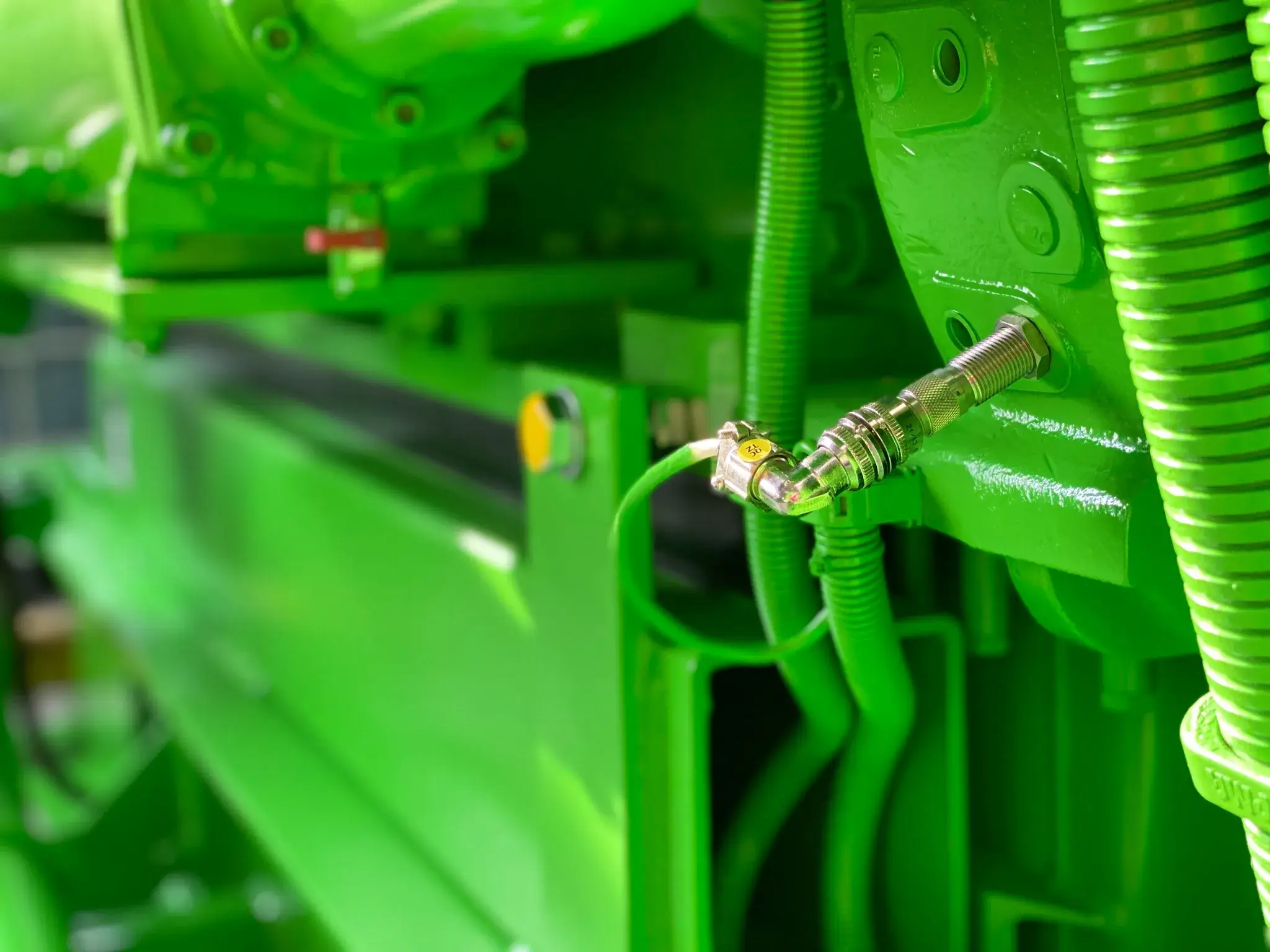

Blowby gas is a hidden efficiency killer in gas engines. Learn how modern filter solutions protect components, cut oil loss, and reduce service costs—backed by real data.

REMAN engines are emerging as the go-to solution in industries where cost-efficiency and performance are key. Through a detailed remanufacturing process that adheres to OEM standards, these engines offer new-like reliability, extended service life, and a smaller environmental footprint. Especially for operators of gas and biogas engines, REMAN units provide a smart, sustainable alternative to buying new—backed by warranties and built for durability. With PowerUP’s expertise, you can ensure optimal performance and reduced downtime, all while supporting a circular economy.

Remanufactured gas engine spare parts play a big role in efficient maintenance strategies. Discover five compelling advantages of using REMAN components—from cost savings to environmental benefits—especially when paired with condition-based overhauls.

What exactly is REMAN, and how does it differ from rebuilt or overhauled engines or components? In this article, we explain the process of remanufacturing, its benefits, and why REMAN plays a growing role in industrial engine maintenance.

In this post we will look into some challenges, such as market fluctuations, that can occur for gas engines. Read on!